Metal Ceilings

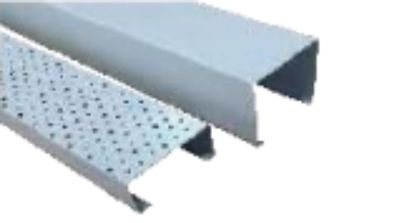

U Shaped Screen

An expansion joint, or movement joint, is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of building materials, and vibration. It also allows movement due to ground settlement or seismic activity. These joints are commonly found between sections of buildings, bridges, sidewalks, and other structures. Building faces and concrete slabs naturally expand and contract due to seasonal variation or other heat sources. Without expansion joint gaps built into these structures, they would crack under the induced stress.

Technical Details

Panels: P50 Panel – 50mm / 150mm /125mm wide, & P25 Panel – 25mm / 75mm / 100mm, 50mm / 100mm deep, length up to 3 meters, Galvanized Steel 0.5mm / 0.45mm & 0.65mm Aluminum – TCT.

Carrier: Various Gap, 25mm / 50mm / 75mm / 100mm made of Galvanized Steel 0.45 / 0.65 mm thick & Alu. 0.95mm thick black.

Paint finish: 55 microns thick powder coating on the exposed surface or 25 microns polyester coil coated over primer on the visible surface with a primer coat on the rear side.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile, End cap, Back cap.

Z Shaped Screen

Z-Shaped Open Screen ceiling profiles that are hung vertically from the suspension to form an open screen linear perspective interior ceilings. It can be seen that Z-Shaped system offers provision for air movement through the ceiling and light fitting, sprinkler etc.

Technical Details

Panels: Height 100mm, width 20mm, length up to 3 meters., Galvanized Steel 0.55mm & 0.71mm Aluminum – TCT.

Carrier: Center to Center 100mm / 75mm, Galvanized Steel 0.45/0.6mm thick stove enamelled black.

Paint Finish: 55 microns thick powder coating.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile.

Open Cell

Open Cell is an innovative product gives an elegant look of the area offering provision for air circulation. When you want to differentiate the interiors, it is available in many cell sizes of 50mm/ 75mm/ 100mm/ 150mm/ 200mm etc. Open Cell Ceiling can be used in areas like Foyers, Passages, Offices, airports etc.

Technical Details

Cell Size: Cell 50mm/ 75mm/ 100mm/ 150mm/ 200mm. Height 40mm & Width 10mm.

Material: Galvanized Steel 0.4mm & Aluminium 0.5mm – TCT

Paint Finish: 55 Microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Accessories: Spring Steel Big Clip, 4mm dia GS Rod, GS / Alu. Edge Profile & “T” Grid System.

Clip-In Tile

Clip-In concealed panels provide durable and monolithic ceilings for interior and can be used in external conditions where the False Ceiling is not directly exposed to rainfall.

Clip-In panels are available in a variety of rectangular and square sizes like 600 x 600mm, 1200 x 600mm, 1200 x 300mm, 300 x 300mm & custom sizes.

It is so Ideal for hospital, clean rooms, food processing area, Pharmaceuticals etc

Technical Details

Panels: For Flush & Concealed look, Square edge tiles of 600 * 600mm / 1200 * 600mm / 1200 * 300mm, 1264* 254mm & Customized.

Material: Galvanized Steel 0.5mm / 0.45mm, Aluminum 0.7mm / 0.65mm, Stainless Steel 0.4mm – TCT.

Perforation Details: 2.5mm, Center to Center in Regular Pattern.

Paint Finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Accessories: GS Clip In Carrier, GS Clip In Carrier Coupler, GS Hold on Hanger, Pressure Clip, 4mm dia GS Rod, height adjustment Spring Steel small Clip, GS / Aluminum Edge Profile.

Lay-InTile

Lay-In tile is most popular bearing system to realize false ceilings with visible 24 mm, 15 mm & Silhouette / center black T grid. Panels are durable and versatile metal panel ceilings available in a wide variety of sizes like 600*600mm, 1200*300mm, 1200*600mm etc. Lay-In tile is simple to install and give easy access to equipment installed above them, allowing rapid intervention & maintenance. Lay-In tegular system provides an economic solution to many ceiling requirement. Various acoustical criteria can be met with the inclusion of acoustical inlays in the back of a perforated tile.

Technical Details

Panels: Square / Beveled edge, 600 * 600mm / 1200 * 600mm / 1200 * 300mm & Customized.

Material: Galvanized Steel 0.5mm / 0.45mm / 0.40mm, Aluminum 0.7mm / 0.65mm, Stainless Steel 0.4mm – TCT.

Perforation Details: 2.5mm, Center to Center in Regular Pattern & Square Perforation, etc.

Paint finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Accessories: Spring Steel Butterfly clip, 4mm dia GS Rod, GS / Aluminum Edge Profile & recommended “T” grid system.

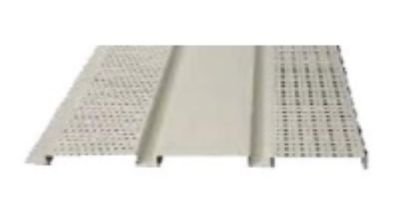

Linear 84C / 184C

Linear 84C has been used extensively on exterior and interior applications and gives designers options for visual design continuity. Panels are clipped into the concealed suspension system to form a closed joint linear ceiling. It will give a rhythm to any Project, where colors & length come together. Various acoustical criteria can be met with the inclusion of acoustical inlays

Technical Details

Panels: Square edge, 84mm wide, 12.5mm deep, length up to 5 mtr.

Material: Galvanized Steel 0.5mm / 0.45mm, Aluminum 0.65mm / 0.71mm – TCT.

Carrier: Carrier shall be 20 mm wide at bottom and 39 mm deep of 0.45/0.6mm Galvanized Steel stove enameled black to hold Panel in module of 100 mm.

Paint Finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Perforation: 2mm dia with 7mm center to center diagonal pattern & 4mm, 2mm combine acoustical perforation.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile.

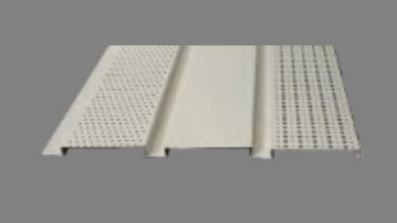

Linear 84R / 184R / with flush cap

Linear 84R Ceiling is known for its attractive and fluid lines. The spaces between the panels may be left open for acoustical or air movement requirements, or closed with separate Flush Cap to give concealed look. Panels can be easily removed & replaced by hand allowing easy and full access to services.

Technical Details

Panels: Round edge, 84mm wide, 15mm deep, length up to 5 mtr.

Material: Galvanized Steel 0.5mm / 0.45mm, Aluminum 0.65mm / 0.5mm, Stainless Steel 0.4mm – TCT.

Flush Cap / Recess Cap: Aluminum 0.5mm to be inserted in 16mm gap between two 84R panels.

Carrier: Carrier shall be 20 mm wide and 39 mm deep of 0.45/0.6mm Galvanized Steel stove enameled black to hold Panel in module of 100 mm.

Paint finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Perforation: 2mm dia with 7mm center to center diagonal pattern & 4mm, 2mm combine acoustical perforation.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile.

Linear 150F

ASP 150F, specially designed arrangement make the Ceiling completely interlocked and air tight for a smooth look & uninterrupted appearance, which are able to withstand extreme wind pressure

Technical Details

Panels: Round edge, 84mm wide, 15mm deep, length up to 5 mtr.

Material: Galvanized Steel 0.5mm / 0.45mm, Aluminum 0.65mm / 0.5mm, Stainless Steel 0.4mm – TCT.

Flush Cap / Recess Cap: Aluminum 0.5mm to be inserted in 16mm gap between two 84R panels.

Carrier: Carrier shall be 20 mm wide and 39 mm deep of 0.45/0.6mm Galvanized Steel stove enameled black to hold Panel in module of 100 mm.

Paint finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Perforation: 2mm dia with 7mm center to center diagonal pattern & 4mm, 2mm combine acoustical perforation.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile.

Multi C (V-groove)

Multi-C (V-groove) Ceiling is a closed ceiling with innovative use. This ceiling system gives flush look with V type groove. It is available in different sizes like 75mm/ 150mm/ 225mm with many colour varieties.

Technical Details

Panels: V groove Edge, 75mm/ 150mm/ 225mm wide and 100mm/ 200mm wide, 15mm deep, length up to 5mtr.

Material: Galvanized Steel 0.45 / 0.5mm & Aluminium 0.65mm / 0.71mm – TCT

Carrier: Carrier shall be 20mm wide at bottom & 37mm deep of 0.60mm Galvanized Steel stove enameled black to hold the panels.

Paint Finish: 55 Microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side. Panel Coupler, Carrier Coupler, GS / Aluminum Edge Profile for interior use. 10 Profile Suspension

Accessories: Height Adjustment Spring Steel Big Clip, 4mm dia GS Rod, Panel Coupler, Carrier Coupler, GS / Aluminium Edge Profile.

Wall Cladding

Wall Cladding Panels can be used as decorative, acoustical and protection purposes. Plain & perforated panels are also available with special decorative surfaces, texture & natural wooden finish. It offers utmost flexibility and freedom of design for areas like conference halls, auditoriums, clubs & resorts, corridors, industry etc.

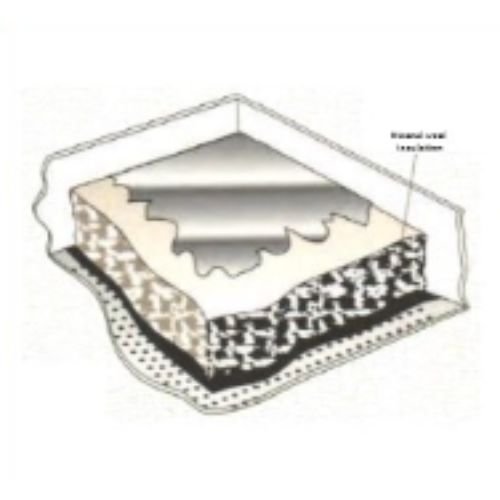

Acoustic

One of main aspects of a Perforated Metal Ceiling is sound absorption. Various types of perforation designs are available. The acoustic properties of a place are, therefore, important elements of environmental well-being, which depends on many physical factors including temperature, humidity & density of the air. Today designers pay great attention to these factors to achieve the desired environmental comfort in relation to the specific use of a building such as classroom, industry, auditorium, office or other.

2.5mm dia round, 5.5mm Centre to Centre in regular Pattern Perforated tile, 16% open area

1.8mm dia round in diagonal Pattern Perforated tile, 20.8% open area

4mm * 4mm Square, 8mm Centre to Centre in regular Pattern Perforated tile, 25% open area

NRC: 0.8 to 0.95 can be achived by use of 25mm thick* 48 kg/m3 density mineral wool,

Aluminiium foil encased and faced one side black glass tissue.

Security and Endurance to External Strains

ASP tiles are mounted up on flexible structures which allow high levels of resistance to external strains and crashes.

Maintenance and Cleaning

For possibly washing the ceiling we recommend to use ordinary detergent or liquid soap. The detergent is to be mixed with water.

Apply the solution by a sponge and wipe off the ceiling by a soft cotton cloth firmly wring in pure water.

Humidity Resistance

Thanks to the Steel and Aluminium qualities,FASP products maintain their properties also in high humidity environments.

This fact makes them suitable for all buildings with unstable temperature range.

Wooden Coating

ASP 150F, specially designed arrangement make the Ceiling completely interlocked and air tight for a smooth look & uninterrupted appearance, which are able to withstand extreme wind pressure

Technical Details

Panels: Round edge, 84mm wide, 15mm deep, length up to 5 mtr.

Material: Galvanized Steel 0.5mm / 0.45mm, Aluminum 0.65mm / 0.5mm, Stainless Steel 0.4mm – TCT.

Flush Cap / Recess Cap: Aluminum 0.5mm to be inserted in 16mm gap between two 84R panels.

Carrier: Carrier shall be 20 mm wide and 39 mm deep of 0.45/0.6mm Galvanized Steel stove enameled black to hold Panel in module of 100 mm.

Paint finish: 55 microns thick powder coating on exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Perforation: 2mm dia with 7mm center to center diagonal pattern & 4mm, 2mm combine acoustical perforation.

Accessories: Height adjustment Spring Steel Big clip, 4mm dia GS Rod, Panel coupler, Carrier coupler, GS / Aluminum Edge Profile.

V72 Half Oval Shaped

ASP V72 half oval shaped panel provide an

extremely efficient form of solar shading by Aerofoil

look.It replace extruded aluminium section in duct

covering and elevation. It is available in a range of

sizes and with a choice of finishes to enhance the

architectural appearance of a building.

Technical Details

Panels: Half oval shaped 50mm wide, length up to 3 mtr., Galvanized Steel 0.5mm –TCT.

Carrier: Various gap, 25mm / 50mm / 75mm / 100mm made of Galvanized Steel 0.6mm thick stove enameled / coil coated black.

Paint Finish: Special high quality surface with Corrosion resistive Super Durable Powder coating,

have properties capable of meeting the severe requirement of exterior applications, preferred with visible & rear both side powder coated.

Accessories: L Clit, Tubular Stud Section, Corrosion, End cap, Back Cap & weather resistive screws and other components if required for structure.

U-Shaped Baffle Louvre

U-Shaped Baffle Louvres are an easily mounted and extremely versatile exterior cladding system.

U-shaped Box is an economic but long-lasting

solution for external cladding. Special unique

Powder coating finish on panel is not affected by dirt and humidity. Shapes, colours, materials and technology, ASP truly offers endless choices. It allows combination of Multi

U Shaped panels, available in wood, metallic and texture finish.

Technical Details

Panels: 50mm / 150mm / 125mm wide, length up to 3 mtr., Galvanized Steel 0.5mm & Aluminum 0.65mm – TCT.

Carrier: Various gap, 25mm / 50mm / 75mm / 100mm made of Galvanized Steel 0.6mm thick stove enameled / coil coated black.

Paint Finish: Special high quality surface with Corrosion resistive Super Durable Powder coating, have properties capable of meeting the severe requirement of exterior applications, preferred with visible & rear both side powder coated.

Accessories: L Clit, Tubular Stud Section, End cap, Back cap, Corrosion & weather resistive screws

and other components if required for structure

84R / 38R Louver

Linear 84R / 38R Cladding is known for its attractive and fluid lines. Panels can be easily removed and replaced by hand allowing easy and full access to services. Their effect is simple but pleasant. Linear Exterior Cladding can be fixed horizontally or vertically with multi space cladding System.

Technical Details

Panel: Round edge, 84mm / 38mm wide, 15 mm deep, length up to 3 mtr.

Material: Galvanized Steel 0.45/0.5mm, Aluminium 0.65mm / 0.71mm TCT

Carrier: Carrier Shall be 20mm wide at bottom and 42mm deep of 0.6mm Galvanized Steel stove enameled black to hold Panel in module of 16mm / 32mm / 42mm. Paint Finish: 55 microns thick powder coating on SL-4 SL-5 H-3 Technical Details 38 76 38 38 65 27 exposed surface or 25 microns polyester coil coated over primer on visible surface with primer coat on rear side.

Accessories: L clit, LAngle (Optional), Tabular Stud Section, Corrosion & Weather resistive screws and other components if required for structure.

U-Shaped Baffle Louvre

ASP Slanted Louvre are highly innovative and

gaining popularity in construction to cover the Ducts and used as a Ventilated facade system.

The systems are easy and fast to install with variety of carriers with different louvers inclination. Panels come with a special high quality powder coating finish.

Technical Details

Panels: 84mm wide, 16mm deep, length up to 5 mtr. made of Galvanized Steel 0.5mm & 0.65mm Aluminum – TCT.

Carrier: Various dimensions (SL-4 / SL-5 / H-3) made of Galvanized Steel 0.6mm, Aluminum 0.91mm thick stove enameled / coil coated black. Paint finish: Special high quality surface with Corrosion resistive Super Durable Powder coating, have properties capable of meeting the severe requirement of exterior applications, preferred with visible & rear both side powder coated.

Accessories: L Clit, L Angle, Tubular stud Section, Corrosion, End cap, Back cap & weather resistive screws and other components if required for structure.